Quality Manufacture

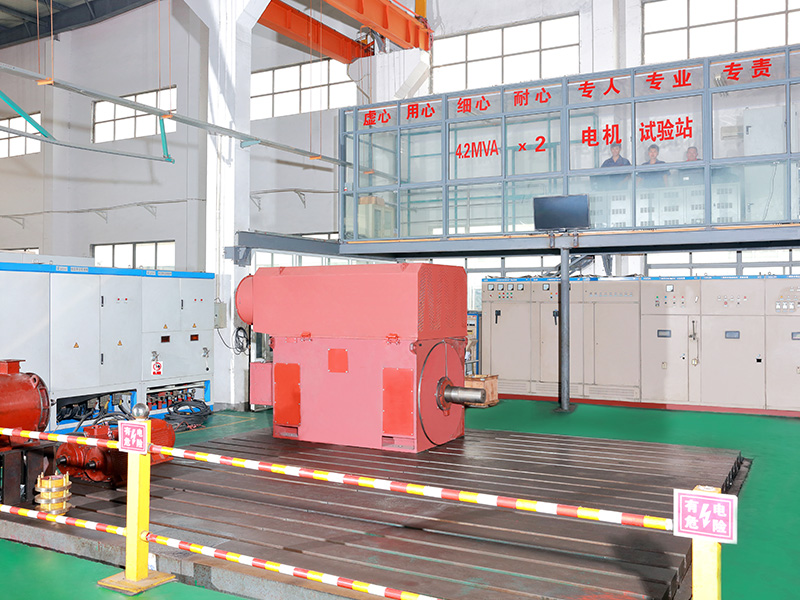

Shanghai Pinxing Motor aims to provide comprehensive motor products and motor technology solutions to global industrial enterprises and various fields. Our company's products are moving towards internationalization in the direction of energy saving, high efficiency, environmental protection, and integrated automation.

Information ManagementPinxing explosion-proof motor production adopts information management: through ERP, MES, barcode management, CRM, PLM, and OA, the resources of marketing, R&D, procurement, production, and sales are optimally allocated, quality is traceable, and timeliness is controllable.

Through market research, we determine the product development direction and product life cycle, and establish an optimized product structure.

Develop new products based on CAD and 3D design systems, optimize the structure for trial production, and finally generate standard production BOM sheets, machining center programs and standard process documents.

Customers log in to our software through electronic devices and input working condition information for computer selection and quotation.

The order enters the ERP system, and subtasks are generated and implemented into warehousing, production, and shipping logistics.

Purchasing the cost-effective products from the qualified supplier database based on the inventory prompts in the ERP and ensuring quality delivery.

Introducing a barcode system to implement all aspects of production, such as finished product delivery. The production process is visible, and product quality is reliable and traceable.

Carry out incoming material inspection, process inspection, shipping inspection, etc. through the barcode system, and upload inspection records in real time to facilitate quality tracking and inquiry.

English

English русский

русский Français

Français عربى

عربى